The authors to thank to whom that shared their experiences to this blog. In addition the assistance provided by the following companies is greatly appreciated: Pharos Indonesia, PT; Pfrimmer Infusol Indonesia, PT; Sinde Budi Sentosa PT; Multi Bintang Indonesia PT Tbk; Griyaton Indonesia PT; for the opportunity to practiced my knowledge at their plant in different periode, finally I can share those experiences to the audience via this blog.

Tuesday, November 16, 2010

Sunday, November 7, 2010

History of Maintenance

It is said that when humans began to use the equipment to transport goods, moving water, plowing farmland and start making building materials, when they were confronted with a reality, the possibility of maintaining these fittings until the time the goods are deemed no longer to used.

By "primitive-thinking" there is no man-made goods that can not be broken, but the age of life (Lifetime) can be extended by doing repairs on a regular basis with a particular activity that then we know as the maintenance.

At the age, the problem mentioned above has to be accepted as true, and for centuries without thinking about how important this issue and its relation to the cost and effort given

By "primitive-thinking" there is no man-made goods that can not be broken, but the age of life (Lifetime) can be extended by doing repairs on a regular basis with a particular activity that then we know as the maintenance.

At the age, the problem mentioned above has to be accepted as true, and for centuries without thinking about how important this issue and its relation to the cost and effort given

Tuesday, November 2, 2010

Plant Inspection.

We already translate it as a factory-examination that in fact is a combination of the activities of both operational and managerial, which includes surveys, data collection, check, measure, detection, examination, analyze, reporting, review test, documentation, recording and auditing or verification.

1. Job scope.

Scope of Plant Inspection other than through the QC Activities implement control and quality assurance through QA Activities of all production equipment that are stationary (Non Rotating Equipments), including preparing permits the use of relevant agencies, both for the unit as well as equipment-operation individually.

Scope of Plant Inspection other than through the QC Activities implement control and quality assurance through QA Activities of all production equipment that are stationary (Non Rotating Equipments), including preparing permits the use of relevant agencies, both for the unit as well as equipment-operation individually.

From my experience as Plant Engineer in several companies, plant-inspection activities include expansion of project activities (expansion), de-bottlenecking, revamping and renovation of the operating units that are under the scope of its responsibilities.

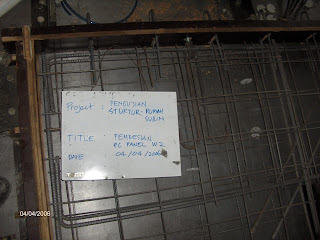

Project activities include QA for engineering, procurement, fabrication, construction and pre-commissioning.

2. QA Activities (Managerial Inspection)

Covers the activities:

2.1 Review of Engineering Documents;

2.2 Vendor List Review;

2.3 Participating in the Pre Bid Meeting;

2.4 Bid Documents Review;

2.5 Attending in Pre-inspecting Meeting;

2.6 Visit Inspection;

2.2 Vendor List Review;

2.3 Participating in the Pre Bid Meeting;

2.4 Bid Documents Review;

2.5 Attending in Pre-inspecting Meeting;

2.6 Visit Inspection;

3. QC Activities

Their activities include such things as follows:

Their activities include such things as follows:

3.1 Receiving Inspection;

3.2 Monitoring in handling Equipments;

3.3 Inspection on Maintaining Works; On & Off Stream Maintenance.

3.2 Monitoring in handling Equipments;

3.3 Inspection on Maintaining Works; On & Off Stream Maintenance.

Indonesian Version.

Kita terlanjur menterjemahkannya sebagai pemeriksaan-pabrik yang pada kenyataannya merupakan suatu gabungan kegiatan-kegiatan baik yang bersifat operasional maupun manajerial, yang meliputi kegiatan survey, data collection, check, measure, detection, examination, analyze, , reporting, review test, documentation, recording dan auditing atau verification.

1. Job scope.

1. Job scope.

Lingkup Plant Inspection selain melaksanakan pengendalian melalui QC Activities dan pemastian mutu melalui QA Activities terhadap semua peralatan produksi yang sifatnya stationer (Non Rotating Equipments), termasuk menyiapkan izin penggunaan dari instansi terkait, baik bagi unit-operasi maupun peralatan secara individual.

Dari pengalaman saya sebagai Plant Engineer di beberapa perusahaan, kegiatan plant-inspection mencakup pula kegiatan proyek perluasan (expansion), debottlenecking, revamping dan renovation dari unit operasi yang berada di bawah scope tanggung-jawabnya.

Kegiatan proyek meliputi QA untuk perekayasaan (engineering), procurement, fabrication, construction dan precommisioning.

2. QA Activities (Managerial Inspection)

Meliputi kegiatan-kegiatan:

2.1 Engineering Documents Review;

2.2 Vendor List Review;

2.3 Participating in Pre Bid Meeting;

2.4 Bid Documents Review;

2.5 Attending in Pre-inspecting Meeting;

2.6 Visit Inspection;

3. QC Activities

Kegiatannya meliputi hal-hal sebagai berikut:

3.1 Receiving Inspection;

3.2 Monitoring in Equipments handling;

3.3 Inspection on Maintaining Works; On Stream Maintenance & Off Stream Maintenance;

Subscribe to:

Posts (Atom)